Russian lathe accidents have become a growing concern in the machining industry, posing significant risks to operators and workers. The increasing number of incidents involving lathes from Russia highlights the importance of understanding the root causes and adopting effective safety protocols. This article will explore the various aspects of Russian lathe accidents, including their causes, preventive measures, and the role of operator training in minimizing risks.

As the machining industry continues to evolve, the use of advanced machinery has become essential for manufacturing processes. However, the complexity of these machines also increases the likelihood of accidents if proper safety measures are not followed. Russian lathes, known for their durability and efficiency, have gained popularity worldwide, but they also come with unique challenges that operators must be aware of.

This article aims to provide a comprehensive guide on Russian lathe accidents, offering valuable insights into the risks involved, potential causes, and strategies to ensure workplace safety. Whether you're an operator, manager, or safety professional, this information will help you better understand the importance of safety protocols in the machining industry.

Read also:Melanie Joly Children A Comprehensive Look Into The Life And Legacy

Table of Contents

- Introduction to Lathe Safety

- Common Causes of Russian Lathe Accidents

- Role of Operator Error

- Machine Maintenance and Safety

- Importance of Safety Training

- Preventive Measures for Russian Lathe Accidents

- Statistics and Data on Lathe Accidents

- Case Studies of Notable Accidents

- Legal and Regulatory Compliance

- Conclusion and Call to Action

Introduction to Lathe Safety

Lathe machines are essential tools in the manufacturing industry, used for shaping and cutting materials such as metal, wood, and plastic. Russian lathes, in particular, are renowned for their robust construction and versatility. However, the complexity of these machines also increases the risk of accidents if proper safety protocols are not followed.

Understanding Lathe Machinery

Russian lathes are designed to handle heavy-duty tasks, making them ideal for industrial applications. Their durability and precision make them a popular choice among manufacturers worldwide. However, the high-speed operations and powerful mechanisms of these machines require operators to be well-trained and vigilant to avoid accidents.

Key Safety Challenges

- High-speed operations that increase the risk of injuries

- Improper use of safety guards and protective equipment

- Lack of proper maintenance leading to mechanical failures

Common Causes of Russian Lathe Accidents

Russian lathe accidents can occur due to a variety of factors, ranging from operator negligence to mechanical failures. Understanding these causes is crucial for implementing effective safety measures.

Operator Negligence

One of the most common causes of Russian lathe accidents is operator negligence. Operators may fail to follow safety protocols, leading to severe injuries or equipment damage. Proper training and regular refresher courses can significantly reduce the likelihood of such incidents.

Mechanical Failures

Mechanical failures, such as worn-out parts or faulty components, can also contribute to accidents. Regular maintenance and inspections are essential to ensure that the machine is functioning correctly and safely.

Role of Operator Error

Operator error is a significant factor in many Russian lathe accidents. Operators may make mistakes due to lack of experience, fatigue, or distractions. Implementing strict safety guidelines and providing ongoing training can help minimize these errors.

Read also:Trey Yingst Wife A Comprehensive Look Into Her Life Career And Relationship

Training Programs for Operators

Effective training programs should focus on both theoretical knowledge and practical skills. Operators should be trained on how to use the machine safely, identify potential hazards, and respond to emergencies.

Machine Maintenance and Safety

Regular maintenance is critical for ensuring the safe operation of Russian lathes. Neglecting maintenance can lead to mechanical failures, increasing the risk of accidents. A well-maintained machine not only operates more efficiently but also reduces the likelihood of injuries.

Importance of Scheduled Inspections

Scheduled inspections should be conducted regularly to identify and address any potential issues before they escalate into major problems. This proactive approach can save time, money, and most importantly, lives.

Importance of Safety Training

Safety training is a vital component of preventing Russian lathe accidents. Well-trained operators are more likely to adhere to safety protocols and recognize potential hazards. Employers should invest in comprehensive training programs that cover all aspects of lathe operation and safety.

Components of Effective Training

- Theory and practical sessions on machine operation

- Emergency response procedures

- Use of personal protective equipment (PPE)

Preventive Measures for Russian Lathe Accidents

Implementing preventive measures is essential for reducing the incidence of Russian lathe accidents. These measures include proper machine setup, use of safety guards, and regular maintenance.

Proper Machine Setup

Ensuring that the lathe is properly set up before operation is crucial for safety. Operators should verify that all components are securely fastened and that the machine is functioning correctly before starting work.

Statistics and Data on Lathe Accidents

Data from various sources indicate that lathe accidents are a significant concern in the manufacturing industry. According to the Occupational Safety and Health Administration (OSHA), machine-related accidents account for a substantial portion of workplace injuries each year.

Key Statistics

- Approximately 8% of all workplace injuries involve machinery

- Russian lathe accidents account for a growing percentage of these incidents

- Most accidents occur due to operator error or lack of maintenance

Case Studies of Notable Accidents

Examining case studies of notable Russian lathe accidents can provide valuable insights into the causes and consequences of such incidents. These case studies can also highlight the importance of safety protocols and preventive measures.

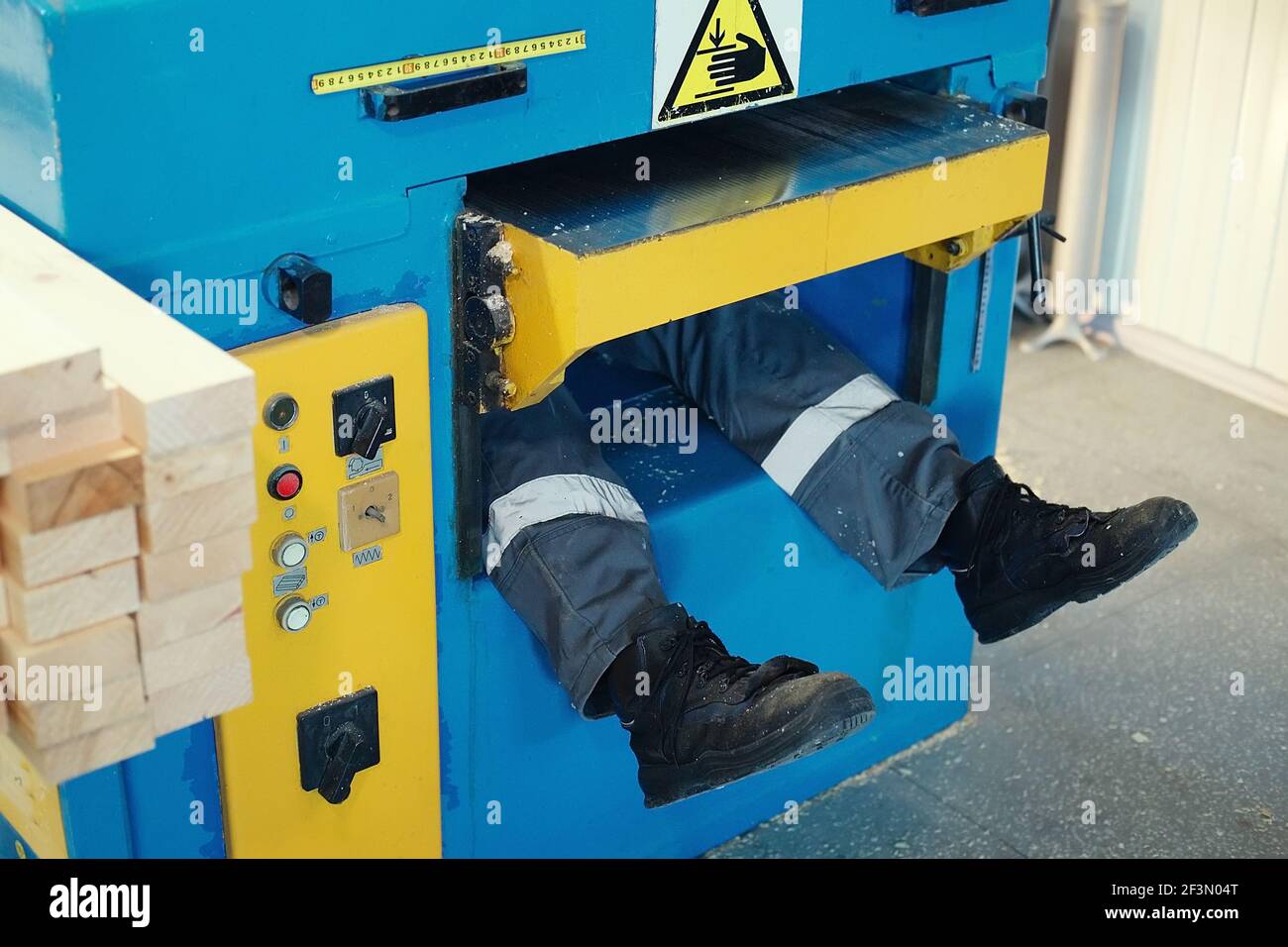

Case Study 1: Improper Use of Safety Guards

In one incident, an operator neglected to use the safety guard while operating a Russian lathe, resulting in severe hand injuries. This case underscores the importance of adhering to safety protocols and using protective equipment.

Legal and Regulatory Compliance

Employers and operators must comply with legal and regulatory standards to ensure workplace safety. Failure to adhere to these standards can result in legal consequences and increased risk of accidents.

Key Regulations

- OSHA standards for machine safety

- Local and national regulations governing workplace safety

- Industry-specific guidelines for lathe operation

Conclusion and Call to Action

Russian lathe accidents pose significant risks to operators and workers, but with proper safety measures and training, these risks can be minimized. By understanding the causes of accidents and implementing preventive measures, employers and operators can create a safer working environment.

We encourage readers to share this article with colleagues and participate in ongoing discussions about workplace safety. Your feedback and insights can help improve safety protocols and reduce the incidence of accidents in the machining industry. Together, we can make a difference in ensuring the safety of all workers.