Accidents involving machinery, such as Russian lathe accidents, are a stark reminder of the importance of safety protocols in industrial settings. These incidents, captured on video, often go viral, highlighting the dangers faced by workers and emphasizing the need for better safety measures. In this article, we will delve into the causes, consequences, and preventive measures related to these accidents, ensuring you gain valuable insights into workplace safety.

With the rise of video-sharing platforms, the footage of these accidents has gained significant attention. While these videos may seem shocking, they serve as crucial learning tools for understanding the risks associated with operating heavy machinery. By analyzing these incidents, we aim to promote awareness and encourage safer practices.

This article will explore the various aspects of Russian lathe accidents, including their causes, preventive measures, and the role of safety regulations. We will also examine real-life case studies and expert opinions to provide a well-rounded perspective on this critical issue.

Read also:Unveiling The Truth Understanding The Controversy Surrounding Buscar Kid And His Mom Cctv Full Video

Understanding Russian Lathe Machines

Russian lathe machines are widely used in manufacturing and industrial settings for shaping metal and other materials. These machines are known for their precision and efficiency, but they also pose significant risks if not operated correctly.

Key Features of Russian Lathes

Russian lathes differ from other types of lathes in several ways:

- They are often more robust and durable, designed for heavy-duty tasks.

- They feature advanced cutting tools and attachments for intricate work.

- They require specialized training to operate safely and effectively.

Understanding the unique characteristics of these machines is essential for preventing accidents and ensuring workplace safety.

Causes of Russian Lathe Accidents

Accidents involving Russian lathes can occur due to a variety of factors, ranging from human error to mechanical failure. Below, we explore the most common causes:

Human Error

One of the leading causes of lathe accidents is human error. This can include:

- Improper training or lack of experience.

- Failure to follow safety protocols.

- Distracted operation or fatigue.

Addressing these issues requires comprehensive training programs and regular safety audits.

Read also:Hsoda030 A Comprehensive Guide To Understanding Its Impact And Relevance

Mechanical Failures

Mechanical failures, such as defective components or inadequate maintenance, can also lead to accidents. Ensuring regular inspections and timely repairs is crucial for preventing such incidents.

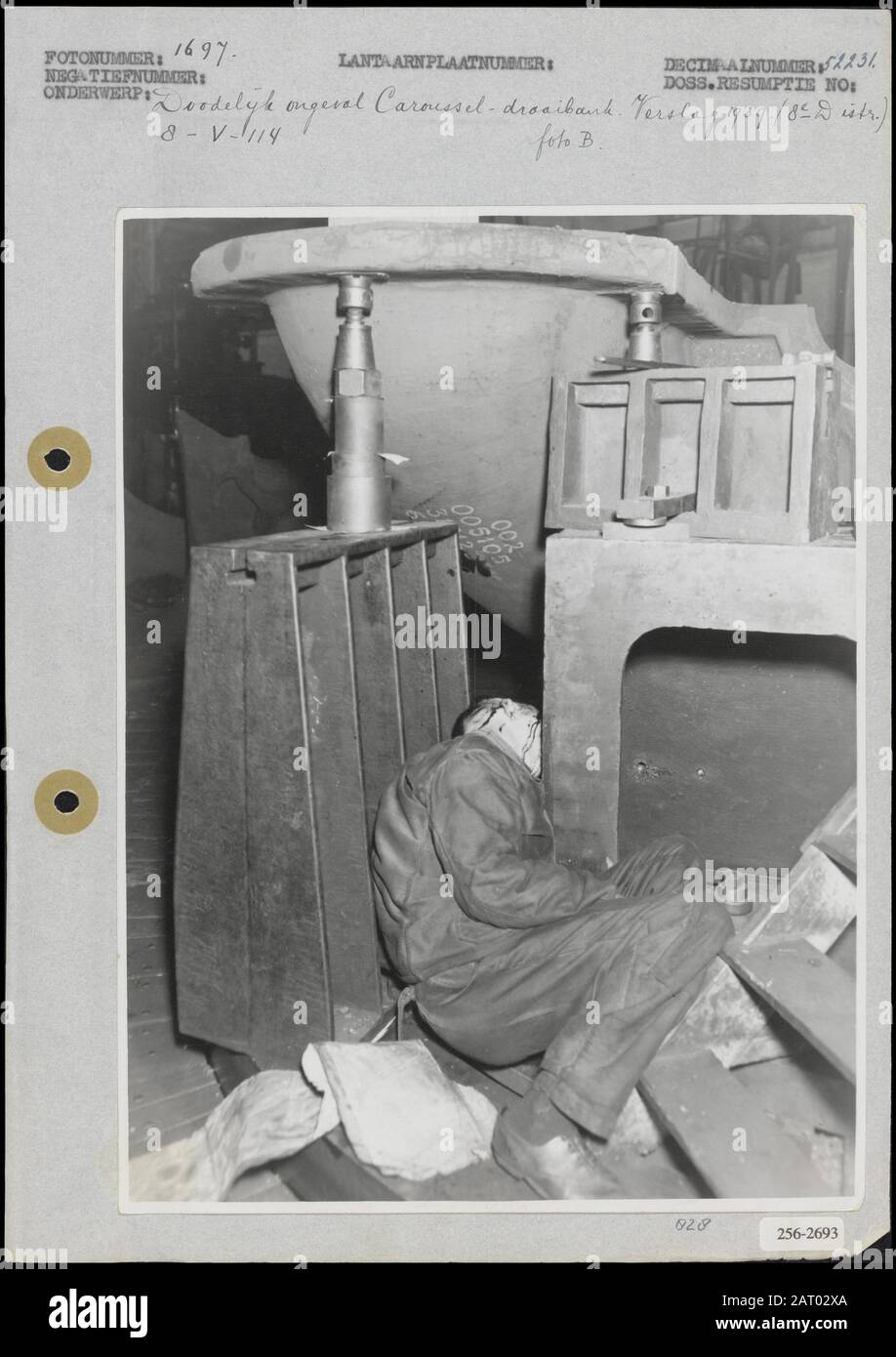

Real-Life Case Studies

Examining real-life case studies of Russian lathe accidents provides valuable insights into the causes and consequences of these incidents. Below are two notable examples:

Case Study 1: Mishandling of Cutting Tools

In this incident, a worker failed to secure the cutting tool properly, resulting in severe injuries. The accident highlighted the importance of adhering to safety guidelines and using appropriate protective gear.

Case Study 2: Neglecting Maintenance

A lathe machine malfunctioned due to neglected maintenance, causing a dangerous situation in the workplace. This case underscores the significance of regular upkeep and inspections.

Preventive Measures

Preventing Russian lathe accidents involves a combination of training, technology, and regulatory compliance. Below are some effective preventive measures:

Comprehensive Training Programs

Providing workers with thorough training on operating lathe machines safely is essential. Training should cover:

- Proper use of safety equipment.

- Understanding machine specifications and limitations.

- Emergency response procedures.

Advanced Safety Technology

Implementing advanced safety technology, such as sensors and automated shut-off systems, can significantly reduce the risk of accidents. These technologies help detect potential hazards and prevent mishaps before they occur.

Regulatory Compliance

Adhering to safety regulations is crucial for preventing Russian lathe accidents. Regulations vary by country but typically include:

- OSHA standards in the United States.

- EU Machinery Directive in Europe.

- Russian labor safety laws.

Staying updated on these regulations ensures compliance and enhances workplace safety.

Impact on Workers and Industry

Russian lathe accidents have a profound impact on both workers and the industry as a whole. The consequences can include:

Physical and Emotional Trauma

Workers involved in accidents often suffer physical injuries and emotional distress. Providing adequate support and rehabilitation is essential for their recovery.

Economic Costs

Accidents can result in significant economic losses for businesses, including:

- Increased insurance premiums.

- Lost productivity due to downtime.

- Potential legal liabilities.

Role of Safety Culture

Fostering a strong safety culture within organizations is vital for preventing Russian lathe accidents. This involves:

- Promoting a proactive approach to safety.

- Encouraging open communication about potential hazards.

- Rewarding safe behaviors and practices.

Leadership commitment to safety is key to creating a culture where accidents are minimized.

Future Trends in Lathe Safety

Advancements in technology and safety practices are shaping the future of lathe machine operations. Key trends include:

Artificial Intelligence and Automation

AI-driven systems can monitor machine performance and predict potential failures, reducing the risk of accidents. Automation further minimizes human error by performing repetitive tasks with precision.

Sustainable Practices

Adopting sustainable practices, such as energy-efficient machines and eco-friendly materials, not only enhances safety but also benefits the environment.

Expert Opinions and Insights

Experts in the field of industrial safety provide valuable insights into preventing Russian lathe accidents. According to a study published in the Journal of Occupational Safety and Health, "Training and technology are the two pillars of a safe working environment."

Industry leaders emphasize the importance of continuous improvement in safety practices, citing the need for regular updates to training programs and safety protocols.

Conclusion

Russian lathe accidents highlight the critical importance of safety in industrial settings. By understanding the causes, implementing preventive measures, and fostering a strong safety culture, organizations can significantly reduce the risk of these incidents.

We encourage readers to take action by:

- Sharing this article to raise awareness about workplace safety.

- Providing feedback or questions in the comments section.

- Exploring additional resources on industrial safety.

Together, we can create safer workplaces and protect workers from preventable accidents.

Table of Contents

- Understanding Russian Lathe Machines

- Causes of Russian Lathe Accidents

- Real-Life Case Studies

- Preventive Measures

- Regulatory Compliance

- Impact on Workers and Industry

- Role of Safety Culture

- Future Trends in Lathe Safety

- Expert Opinions and Insights

- Conclusion